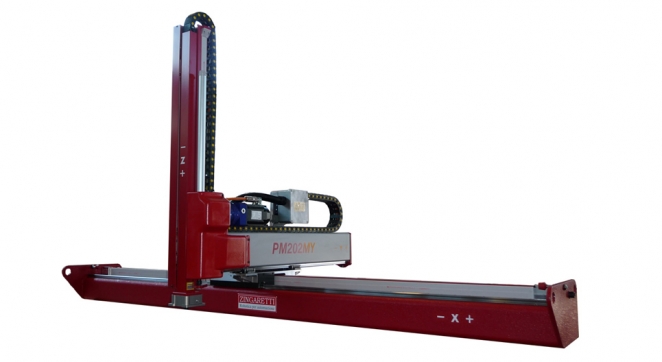

RT202MY

Servo system robot for injection molding machines for plastic materials from 200 to 500T.

The evolution of the intermediate series of Robot Zingaretti is the result of experience and knowledge developed over time. Built with aluminum profiles, special, special cast aluminum, telescopic Z axis and Y axis movement, the robot MY RT202 is a concentrate of technology.

It's small, but it does great things - zero ordinary maintenance

- Using new tecnlogie

- Telescopic Vertical Axis

- Structure with special aluminum profiles

- All moving parts lubricating

Main Characteristics

- PLC Modicon / Telemecanique control + axes tab or CNC dedicated

- Total Man-machine dialogue with video-keyboard touch screen applied to the side of the press

- Axes are moved with brushless motors

- Transmissions with reducers Stober gears and heavy-load timing belts

- X axis working travel… 1500 – 2000 – 2500 – 4000 mm

- Y axis working travel… 730 mm

- Z axis working travel… 1250 – 1500 mm

Main Programs and functions

- Cycle of development in Teach

- interpolated movements

- Discharge to the right or left

- vertical rotation

- Radial rotation 0-90° / 0-180°

- Gripping pliers with tongs

- Control grip piece with sensor or photocell

- Pneumatic controls on the gripping configurable

- Gripping devices interchangeable

- tape command

- Discharge printed on multiple positions

- Unloading pallets in layers or columns

- Unloading pallets vacant positions

- Options “Waiting exhaust”

- Option “Draining different” if busy

- Labeling command to the left or right-configurable

- Socket sprue with the presence of Fc piece

- Loading and unloading inserts

Options

- Custom Programs